What Is Radiant Heat?

Radiant (underfloor) heating is a type of heating system that is placed below the floor of a building. Radiant heating as a technology is the method of intentionally using the principles of radiant heat to transfer radiant energy from an emitting heat source to an object. Radiant heating may be either hydronic (water/fluid flowing through pipes) or electric (electric resistance heating elements).

The temperature of the floor surface is the key to determining what level of comfort is necessary. End-users may feel uncomfortable when coming in contact with floor surfaces that are too warm or too cool. Thermal comfort is defined by building scientists and health care professionals as “a condition of mind that expresses satisfaction with the thermal environment.” Radiant heating and cooling systems are commonly used when addressing human thermal comfort (even though radiant cooling systems are never recommended for use under wood flooring).

To provide an adequate thermal environment for the end-user, many factors must be taken into account, including the size of the room, the construction of the home, R-value of the windows, HVAC systems, the number and age of the occupants, and the interior finishes that may be directly affected by these requirements.

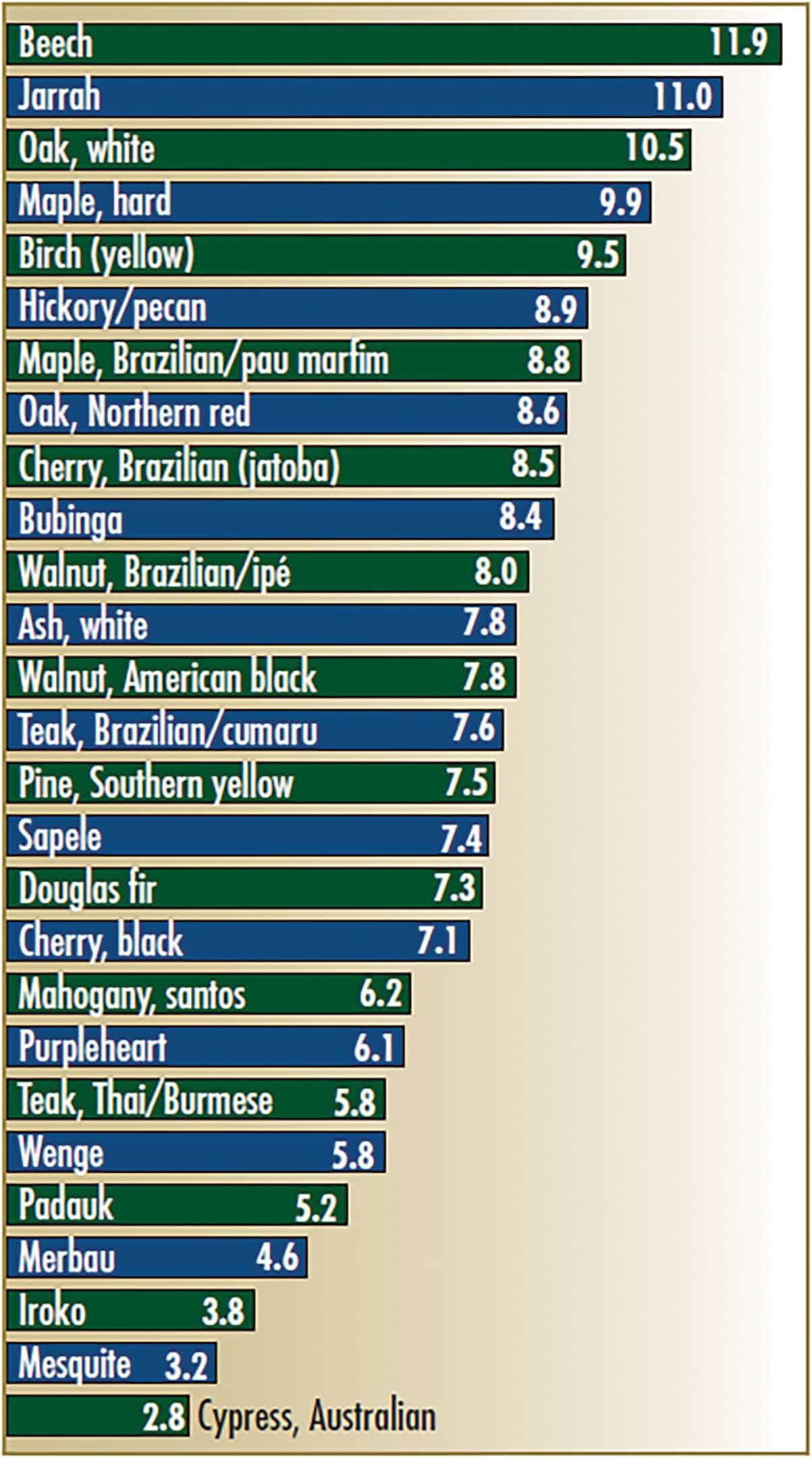

The ability/inability of a wood flooring material to transfer heat will directly affect the radiant heating system design. The ability of the radiant heating system to either adequately heat the facility, or to simply warm the floor, without damaging the wood, must be taken into account when specifying a radiant heating system within any facility.

Important Things to Keep In Mind

All wood flooring should be properly matched to the expected live-in conditions in which it will perform. With the heating source placed directly below the installed wood flooring, the moisture content will forcibly be reduced during the heating season if supplemental humidification is not added.

A supplemental humidity control system will often be necessary, and should be specified into the project, to properly support the wood flooring manufacturer’s environmental requirements, or when not specified, to support ambient airspace conditions between 30 percent to 50 percent RH, and 60° F-80° F, per NWFA Installation Guidelines. The wood flooring professional should confirm and document if a supplemental humidification system is present and operational before the specification or installation of the wood flooring.

In-floor or under-floor data loggers are recommended to be installed by the flooring contractor to ensure the temperature and humidity conditions do not exceed flooring tolerances. Placement of these sensors should be determined with the assistance of the radiant heating system installer to gain the most accurate floor temperature readings.

The end-user should be made aware of the importance of proper usage and maintenance of the humidification system and data loggers to ensure adequate temperature and relative humidity levels are maintained year-round.

Best Wood For Radiant Heat

Cut, Width, and Flooring Type

Quartersawn and riftsawn wood flooring are more dimensionally stable in width than plainsawn or end-grain wood flooring.

Wood changes dimension proportional to the width of the plank. Narrow boards expand and contract less than wider-width boards of the same species and cut.

Engineered wood flooring is, in general, more dimensionally stable than solid wood flooring. However, not all engineered wood flooring is recommended or appropriate for use over radiant heating systems. Engineered flooring with a less-stable wear layer species such as hickory, beech, and maple are not normally best suited over radiant heat unless otherwise suggested by the flooring manufacturer. The cut and thickness of the wear layer lamina (peeled, sliced, or sawn) may also affect how the floor performs over radiant heat. Follow the flooring manufacturer recommendations for maintenance, environmental (T and RH) requirements, surface temperature requirements, and whether or not each specific product is intended to be used over radiant heat.

Most wood flooring can be installed over radiant heat, providing all of the necessary conditions are met. Successful wood floor installations occur when the radiant heat system design engineer, the radiant heating system installer, the wood flooring installer, and the end-user all communicate and fully understand what is required for the entire flooring system being installed. This communication should include which type of wood flooring to use, what installation method to use, understanding how this heat source may impact the wood flooring, what precautions to take before, during and after installation, and consistent communication among all parties when any changes take place to any part of the system. The end-user should also have a clear understanding of the flooring product use and maintenance requirements, as well as the radiant heating system features, limitations, and capabilities, and how all of these work together within the system, to stay

within the necessary parameters.

Article written by Brett Miller and edited to fit our specifications. Brett is the VP of Education & Certification at the National Wood Flooring Association in St. Louis. He can be reached at brett.miller@nwfa.org.